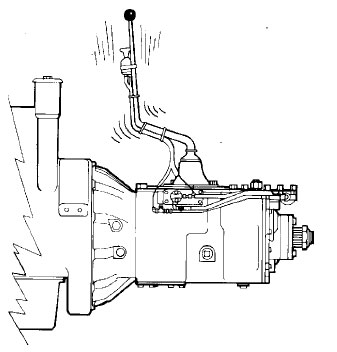

Eaton Fuller Transmisyon depanaj Gid

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, asistans lokalize pwoblèm nan nan pwoblèm transmisyon, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 ak 18 pi vit Eaton transmisyon. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Fonksyon an transmisyon se avèk efikasite transfere pouvwa motè a nan, an tèm de koupl, nan wou dèyè machin nan. Koupl se trese an oswa fòs sikilè delivre nan volan motè a nan. rapò Kovèti pou transmisyon a ogmante oswa diminye koupl depann sou kondisyon ki nesesè pou avanse pou pi oswa kòmanse chay la. Angrenaj tou ogmante oswa diminye vitès. rapò yo Kovèti pou yo kòrèkteman espace pou ke motè a pral opere nan seri ki pi efikas RPM li yo ak chanjman vitès pwogresis. Pou satisfè kondisyon veyikil la nan, transmisyon a dwe gen rapò ki ba ase yo kòmanse machin nan k ap deplase, yo kenbe mouvman leve-klas, ak kenbe motè a opere nan seri efikasite gwo monte li a. transmisyon nan, twò, dwe bay yon metòd fasil pou Kovèti pou seleksyon.

Gid depanaj pou modèl sa yo transmisyon Eaton Fuller:

Komen Transmisyon Plent

Vibwasyon

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; sepandan, nan kèk ka, transmission damage caused by vibration will occur without the driver’s knowledge.

Gen kèk Pwoblèm Transmisyon Akòz Kondwi tren Vibwasyon:

- Kovèti pou tchatcha a san fè anyen konsa

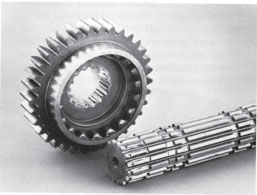

- Kovèti pou & shaft splines (fretted)

- Bri

- fretted bi

- Repete dèyè flit sele

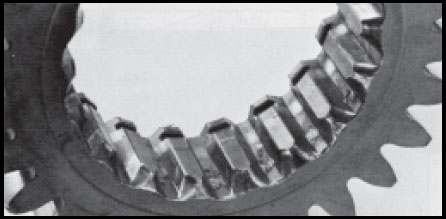

- Pins Synchronizer Broken oswa ki lach

- Kontini detachman nan capscrews, parantèz ak garnitur

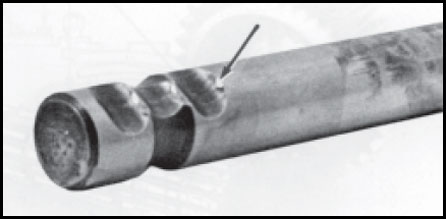

- Chire aks kolòn vètebral Mete

- Worn universal joints (Pa yon sentòm transmisyon, men yon endikatè a Vibration.)

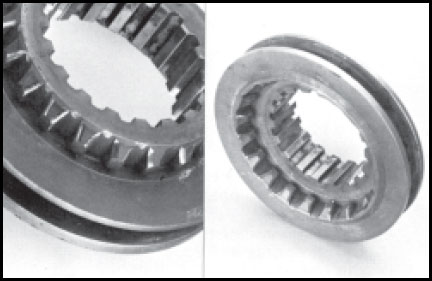

fretted kanlur

Broken Synchronizer Pins

Antre Atèl Mete

Common causes of vibration include driveline imbalance or misalignment, dezekilib wou oswa tanbou fren, ki graj motè kouri, kase oswa chire mon motè ak sispansyon chire.

Kovèti pou Slipout ak Jumpout

Front Seksyon

Lè yo bay yon anbreyaj glisman demenaje ale rete nan angaje ak yon Kovèti pou Mainshaft, dan yo kwazman dwe paralèl. Kon oswa chire seran dan pral eseye "mache" apa kòm angrenaj yo Thorne. Anba kondisyon yo dwa, slipout, sa pral lakòz. Gen kèk nan kondisyon sa yo, se:

- Transmisyon monte èksantrikman ak motè volan pilòt.

- Twòp eurte Kovèti pou ki rakoursis dan seran.

- Kòrèk ajisteman nan chanjman aleka koneksyon kontwòl sa ki lakòz angajman yon pati nan. Tcheke tou pou koneksyon ki lage ak kousinen chire.

Snubbed seran Dan

Kovèti pou seran dan mete nan yon flanbo.

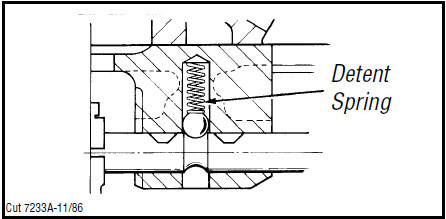

DETENT Spring

Ensifizan presyon sou boul DETENT soti nan fèb oswa kase sezon prentan DETENT.

Chire jouk bèf Bar

Twòp mete sou DETENT dan nan kou ba

Kondisyon ki kapab lakòz Jumpout

- Siplemantè levye lou ak long chanjman ki balanse, pandil mòd, soti nan opere sou tèren inegal. Fwete aksyon nan levye a genyen batay DETENT tansyon sezon prentan.

- Mechanical rimot kontwòl ak mèt la monte nan ankadreman an. mouvman relatif ant pake motè-transmisyon ak ankadreman ka fòse transmisyon soti nan Kovèti pou. Chire oswa mon motè kase ogmante efè yo nan kondisyon sa a.

oksilyè Seksyon

Slipout in the auxiliary section may be caused by the clutching teeth being worn, kon, oswa ou pa konplètman angaje. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Kòm koupl se reaplike, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

Hard itinerant

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

Pifò plent yo ki la avèk detay sou kalite aleka yo itilize nan machin cabover-motè. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, obligatwa, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. Pou detèmine si transmisyon nan tèt li se kòz la nan déplacement difisil, retire levye a chanjman oswa koneksyon nan tèt la nan transmisyon an. Lè sa a,, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, pwoblèm nan se ak tout pèp la koneksyon. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- ba jouk bèf obligatwa nan lojman an ba kòm yon rezilta nan fann lojman, sou-torqued chanjman blòk lockscrew, sprung yoke bar, or swelled areas of the yoke bar.

Si difisil déplacement fèt sèlman nan premye ak ranvèse, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, Lè sa a, te apiye soti 1/4 to 1/2 vire.

Kovèti pou eurte pa ta dwe konfonn ak déplacement difisil. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

chalè

The transmission operating temperature should never exceed 250°F (120° C) pou yon peryòd pwolonje nan tan. Si li fè sa, the oil will breakdown and shorten transmission life.

Paske nan friksyon an nan k ap deplase pati, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Anvan tcheke pou sa ki lakòz posib pou surchof, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. move lubrification. nivo lwil oliv twò ba oswa twò wo, wrong type of oil, or an operating angle of more than 12 degre.

2. Opere toujou anba 20 MPH.

3. Segondè motè RPM.

4. Restricted koule lè alantou transmisyon, due to the transmission being “boxed in” by frame rails, deck lids, tank gaz ak aliye parantèz, or by a large bumper assembly.

5. Emisyon gaz sistèm twò pre transmisyon.

6. Segondè tanperati anbyen.

7. segondè puisans, chaje operasyon.

8. Kotyèr desann ak anbreyaj a deprime.

Nan kèk ka, an external oil cooler kit can be used to correct overheating problems.

Transmisyon Refroidisseurs lwil oliv yo:

rekòmande

- Avèk motè a 350 H.P. and above with overdrive transmissions

obligatwa

- avèk motè 399 H.P ak pi wo a ak chaje

transmisyon ak GCWs sou 90,000 liv. - avèk motè 399 H.P. ak pi wo a ak 1400 Lb-pye.

oswa pi plis koupl - avèk motè 450 H.P. ak pi wo a

transmisyon Bri

There will always be a certain level of noise due to the normal transmission operation. Sepandan, excessive noise or unusual noise such as a whine, gwonde, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. Epitou, noise can originate elsewhere in the vehicle, men ou dwe ranmase ak anplifye pa transmisyon a.

1. Frape pi rèd toujou oswa Thudding

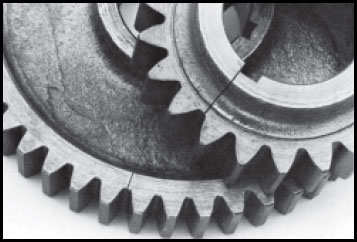

- Angrenaj - bos oswa anfle sou dan Kovèti pou. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. Anjeneral, this noise is more prominent when the gear is loaded; konsa, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- Bi – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- Cracked Kovèti pou – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Nan vitès segondè yon rèl ap prezan.

2. High Pitched Whine or Squeal

- Kovèti pou Mete - Rezilta nan mete Kovèti pou nòmal, including gear tooth pitting from excessive use. In advanced deterioration, yon rèl, sa pral lakòz.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Bi - "kwense" bi, having insufficient axial or radial clearance

3. Grundman

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- Ki graj ralenti motè. (wè Kovèti pou tchatcha)

- Engine opere bri.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Transmissions soti nan balans.

- Inegal ang k ap travay jwenti.

- Chire kwaze nan jwenti inivèsèl.

- Ki lage oswa ki chire sant bi.

- Chire oswa opoze dan sou Kovèti pou bag ak lye nan kondwi aks.

- Aryè aks kote yo pote echèk.

- Wou soti nan balans.

- Chire sezon prentan pivot portant.

- Ki Lage "U" boulon.

- tanbou fren deformation oswa soti nan balans.

Oryantasyon Transmisyon Depanaj la

Following is a basic procedure guideline for troubleshooting transmissions:

- preliminè Enspeksyon

- pèsonèl Obsèvasyon – look for signs of misuse such as broken mounts, ekipman oswa parantèz; check airlines.

- Kesyon pwopriyetè a oubyen Operatè – gather information on operating conditions and vehicle use, sou istwa a nan pwoblèm nan, and on shifting characteristics if affected.

- Rasanble Istwa nan Inite – including maintenance and lubrication procedures, echèk sot pase, ak kantite mil oswa èdtan nan sèvi ak.

- demont Transmisyon

- Kenbe echantiyon lwil pou enpurte, tcheke si sa nesesè.

- pandan demonte, check for incorrectly installed parts, pati ki manke, and nongenuine parts.

- Debarase m de ak enspekte chak moso ak anpil atansyon.

- Detèmine Kalite Si

- Detèmine ak kòrèk Kòz Si

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Jwenn pwoblèm nan transmisyon nan bwat ki anba a

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Gade nan lis ki anba a ak jwenn nimewo ki koresponn lan ki nan lis akote pwoblèm nan. Nimewo a matche nan lis la pral di w koreksyon nan posib.

4) Gen dwa gen plis pase yon kòz posib ak posib koreksyon pou chak pwoblèm.

Koreksyon posib:

- Montre chofè sou teknik kondwi apwopriye.

- ranplase pati (after trying other listed possible corrections).

- Desere fèmen-vis ak rsere koupl apwopriye.

- Gade pou domaj resultant.

- Lis ak papye Emery.

- Reyajiste espesifikasyon bon.

- Enstale manke pati.

- Tcheke konpayi avyon oswa kawotchou.

- sere boulon pati.

- Korije restriksyon nan.

- verifye distribisyon.

- Netwaye pati.

- Aplike mens silicone fim.

- aplike selan.

nenpòt pati transmisyon ou bezwen nou genyen li! Menm jou anbake disponib, atravè lemond.

BEZWEN GRATIS SIPÒ NAN youn nan ekspè NOU?